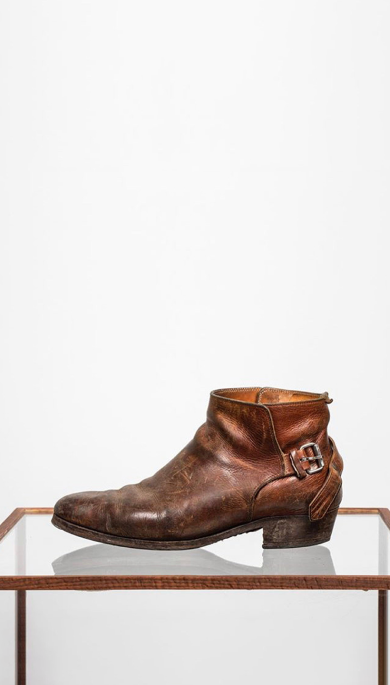

Bespoke Shoes

“Our approach to bespoke shoemaking is that of close collaboration. Precisely constructed to fit our client perfectly, KLH bespoke shoes are conceived in a way that will impart their wearer with an inner and outer stance.”

- Korbinian Ludwig Hess

We are a bespoke shoe atelier, based in Berlin. Our mission is to bring the age-old techniques we have learned from Europe’s best in Vienna, London and Florence into the now: through contemporary yet classic design and constant innovation. Working with the highest-quality and sustainably sourced leather, we produce solely in our Berlin workshop, by hand, without any electric machines. Our shoes take a minimum of six months to make- why? Because we build them to last a lifetime.